Sometimes its wise to combine supercaps with lithium hybrid storage systems; other times its crucial to find the ideal battery cell for a specific task profile. Whatever it takes, Ansmann Group’s battery system experts take a broad 3-step-approach, when it comes to finding the optimized battery and charging system for an application – like for example Driverless Transportation Systems and Automated Guided Vehicle Systems (AGVs) or Autonomous Mobile Robots (AMRs).

Sometimes its wise to combine supercaps with lithium hybrid storage systems; other times its crucial to find the ideal battery cell for a specific task profile. Whatever it takes, Ansmann Group’s battery system experts take a broad 3-step-approach, when it comes to finding the optimized battery and charging system for an application – like for example Driverless Transportation Systems and Automated Guided Vehicle Systems (AGVs) or Autonomous Mobile Robots (AMRs).

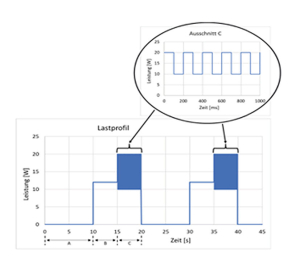

As a result of step one – dare to think out of the box -, a new hybrid storage system for AGVs and AMR , designed by ANSMANN and the IFL Karlsruhe (Institut für Fördertechnik und Logistiksysteme of KIT-Karlsruhe), combines the best of two energy storage worlds: supercap capacitors and lithium-ion (LiIon) battery cells. (See resp. articles) This creates a highly efficient energy storage system, specifically for the needs of a logistic system with AGVs and AMRs. When the double-layer capacitors (so-called ) and battery cells are skillfully combined, the new solution is 50 percent lighter, permanently available and has three times the service life of previous battery applications in AGVs.

The reason for this is, that supercaps can be quickly charged to 95 percent within 30 seconds at precisely located decentralised charging points. The vehicle is then ready for its next tour and can successively charge the conventional battery module to supply the vehicle with energy for longer distances, which cannot be covered by the supercap alone. The result: a perfect, extremely energy efficient hybrid energy storage system for mobile logistic solutions – which is almost half the size with up to 80 percent less battery cells and requires less capacity for identical applications than normal LiIon systems would need.

++ Cell preselection in the new Ansmann battery laboratory and AI-tool

Second, it is crucial for each mobile solution which cells are used in its battery pack. Therefor hundreds of different cells – over 300 round cell types, 60 prismatic and 40 others yet – are recorded in the ANSMANN cell database. For more than two years now, a team of ANSMANN experts is systematically searching for new cell types worldwide and tests them for unusual parameters. The reason for the company’s decision to invest in and systematically expand cell measurement and benchmarking in the form of a “battery laboratory” is obvious: the number of cell sizes is constantly increasing. The number of cell chemistries and cell manufacturers is increasing. However, the cell manufacturers’ data sheets often only reveal a limited part of the truth and only under ideal conditions, but tells nothing for example about very important selection criteria like the behavior of a cell in its aging process.

But: The use of unsuitable cells can have a significant negative impact on the performance and service life of a battery pack and the mobile solution it is used in. Whatever the critical selection criteria were, be it current output capability, acceleration or other: the performance of the battery pack is impaired. Through careful, preventive cell selection, complaints are minimized and the warranty period for the unaffected runtime of the battery pack can be extended to reduce costs.

And even more: For deciding about the best cell forms for the specific solution ANSMANN Industrial Services additional to their BatteryLab to chose the most recommendable cells. Plus ANSMANN has developed an AI-tool, that helps to optimize the pack designs and formats. Learn more about ANSMANN INDUSTRIAL in this video.

+++ Why ANSMANN battery packs?

ANSMANN Industrial Solutions is one of the most long-term reknown European One Stop Shops for battery packs and chargers. The ANSMANN development team located in Germany supports its custormers in their complete development process of battery packs and chargers. From consulting to development to testing to distribution and disposal. Read more